Gasification is a process technology that converts solid material into gas. This process can be performed on fuels such as biomass, coal, and charcoal from the oil refinery process. Gasification wood and boilers also important think in gasificaion area. The gases coming out of the gasification process are mostly carbon dioxide (CO2), carbon monoxide (CO), hydrogen (H2) and methane (CH4).

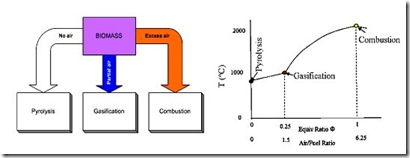

Gasification is different with pyrolysis and combustion. The three distinguished based on the needs of air needed during the process. If the amount of air / fuel (AFR, air fuel ratio) equals 0, then the process is called pyrolysis. If the AFR is required during the process of less than 1.5, then the process is called gasification. If the AFR is needed during the more than 1.5, then the process is called combustion (see picture below).

Fig. Differences pyrolysis, gasification and combustion.

Gasification material including gasification wood reactor can be divided by:

1. based on fluidization mode.

2. Based on the direction of flow.

3. Based on the gasification agent during the process.

Based on fluidization mode, gasification reactor can be divided into fixed bed gasification, moving bed, fluidized bed, and entrained bed. Type of gasification can be described as follows.

Based on the direction of flow, gasification reactor can be divided into unidirectional flow gasifier (downdraft gasification) and counterclockwise flow gasifier (updraft gasification). In downdraft gasification, gas flow direction and the direction of solids flow is equally down. In updraft gasification, solids flow downward direction while the direction of gas flow upward.

Based on the need for gas gasification process, there are air gasification and steam gasification. Air gasification where gas is used for the gasification process is the air while the steam gasification uses steam during the process. ((Sumber:kajian-energi.blogspot..com)

No comments:

Post a Comment